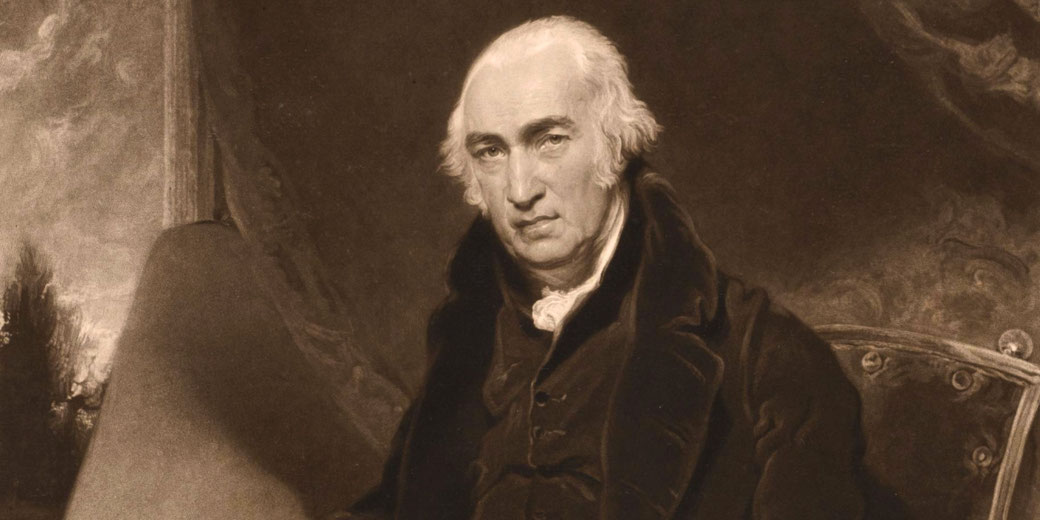

James Watt’s remarkable invention that created the modern world

In the late eighteenth century, one invention changed how humans produced power and organised labour. The steam engine, which was redesigned by James Watt, became the foundation of industrial development and economic growth.

His careful improvements enabled factories, mines, and transport systems to run with greater efficiency and flexibility than ever before.

The problems with early steam engines

Steam engines existed before Watt’s involvement, yet their practical applications remained limited because they caused large energy waste.

Thomas Newcomen’s atmospheric engine, which was introduced in 1712 and was first installed at Dudley Castle, relied on atmospheric pressure and used steam to create a vacuum in a single cylinder.

Inside this chamber, steam condensed to pull a piston downward, which in turn operated a beam that powered a pump.

Many miners across Britain adopted the design because it successfully removed water from flooded shafts, which allowed coal production to expand in many areas.

Typically, each cycle required the cylinder to cool and reheat, which consumed large amounts of fuel and slowed operation.

Watt later estimated that his engine could use up to 75% less coal than the Newcomen design under ideal conditions, though actual savings varied by application.

As the metal contracted and expanded with each cycle, wear often increased and maintenance costs rose.

Engineers and inventors attempted to improve Newcomen’s design, yet their efforts rarely succeeded because they lacked both the scientific knowledge and the technical skill to address the wastefulness of the engine’s main mechanism.

The basic principle of alternating temperature inside a single cylinder placed a hard limit on energy efficiency.

By the mid-eighteenth century, many industrialists required engines that consumed less coal and occupied smaller spaces, which permitted more varied mechanical tasks to be performed.

Water power remained common, yet it depended on location and seasonal availability, which restricted factory placement and output.

The growing complexity of manufacturing systems demanded new machines that could produce continuous, controllable motion without reliance on weather or terrain.

The limitations of the Newcomen engine became increasingly obvious as Britain’s industrial economy expanded.

James Watt: The innovator

James Watt, who worked as an independent instrument maker in a workshop at the University of Glasgow, encountered the Newcomen engine in 1763 when professors asked him to repair a small demonstration model.

Through his work, he recognised that the engine lost significant energy because it repeatedly reheated and cooled the same chamber.

After he had investigated the problem further, Watt designed a system where the steam condensed in a separate chamber so the main cylinder stayed hot during operation.

By 1765, Watt had developed and tested a small-scale model of this innovation at Glasgow University, though it would take another decade before a full-scale engine became operational.

The separate condenser largely eliminated the need for repeated reheating, which allowed the engine to perform more cycles with the same amount of fuel.

His design more than doubled the energy efficiency of the standard engine and made steam power suitable for a wider range of tasks across several industries.

When he applied scientific principles to solve the mechanical problem, Watt demonstrated how thermodynamic theory, particularly the concept of latent heat, which his colleague Joseph Black had defined, could directly improve industrial machinery.

Over the following decade, Watt continued to refine his machine. He introduced a steam throttle valve, which allowed operators to control the engine’s power output.

He later invented a double-acting piston, which used steam pressure on both strokes, and he adapted a centrifugal governor, which had previously been used in windmills, to regulate steam input automatically and maintain a steady speed.

In 1781, he patented the sun-and-planet gear, which converted the piston’s vertical motion into rotary motion and enabled engines to drive machinery directly.

Each new element substantially increased the machine's reliability, made it easier to adapt to different tasks and improved its consistent performance.

To express the output of his engines, Watt introduced the term "horsepower," which gave clients a clear comparison between his invention and traditional draft animals.

Although Watt possessed exceptional technical skill, he lacked the funds and workshop capacity to manufacture the engine at scale.

His early attempts to produce and market his machine had failed to meet demand because he did not yet have a business partner with the necessary financial and organisational resources.

Why were Watt’s designs revolutionary?

Watt’s steam engine differed from earlier models in more than one key area. The separate condenser transformed it into a practical energy source for tasks that required continuous motion, which made it far more than a stationary pump.

Because it maintained a high operating temperature in the main cylinder, the engine conserved fuel and reduced wear, which made it cost-effective for use across industries including mining.

With the introduction of rotary motion, Watt made it possible for steam engines to turn wheels and power machines through axles, gears, and belts.

As a result, factories no longer relied on waterwheels or human power.

Manufacturers could now operate workshops in locations previously considered unsuitable, such as flat inland areas or crowded cities, which helped accelerate urban growth and concentration of industry.

The improvement in energy delivery meant that more machines could run at once, which raised productivity and allowed for more complex manufacturing systems.

Because they addressed both mechanical reliability and energy conservation, Watt’s designs encouraged other inventors to experiment with high-pressure systems, mobile engines, and new materials.

The success of his machine established that heat could be turned into useful motion, which gave engineers a foundation for future research.

His careful attention to mechanical design, based on a clear understanding of thermodynamics, pushed industrial engineering into a new phase of more organised innovation.

Watt’s vital partnership with Matthew Boulton

In 1775, James Watt secured a partnership with Matthew Boulton, who was the owner of the Soho Manufactory in Birmingham.

Boulton brought capital together with access to skilled craftsmen and established supply chains, which together strengthened the firm's political influence.

That same year, Parliament renewed Watt’s 1769 patent, titled "A New Invented Method of Lessening the Consumption of Steam and Fuel in Fire Engines", until the year 1800, which largely protected their investment and gave the firm a strong advantage over competitors.

Together, they formed the firm of Boulton & Watt, which became Britain’s most prominent supplier of steam engines.

Under Boulton’s management, the company focused on producing machines for reliable commercial use.

He arranged contracts with mines, mills, breweries, and other industrial firms. He also invested in staff training and standard production methods, which allowed the firm to deliver consistent quality.

While Watt worked on technical refinements and drawings, Boulton supervised manufacturing and marketing.

Their complementary roles helped them scale up production in a way that no previous engine maker had achieved.

As their engines became known for efficiency and long life, Boulton & Watt received orders from across Britain and Europe.

They installed engines in tin mines in Cornwall, textile mills in Manchester, and ironworks in the Midlands, including the Albion Mill in London.

By 1800, the firm had installed over 500 engines, and their widespread adoption became a significant factor in shifting industrial energy from natural sources to steam power.

The impact on industry and society

Because they made steam power more economical and adaptable, Watt and Boulton helped drive the growth of the Industrial Revolution.

Their engines allowed many manufacturers to increase output, reduce costs, and operate machinery that had previously required human or animal labour.

Factories that once relied on water or wind could now operate consistently, regardless of season or weather, which stabilised production and encouraged long-term investment.

As demand for steam power grew, so too did the industries that supplied fuel, metal, and transport.

Coal mining expanded rapidly to supply the engines, while iron foundries developed new techniques to produce stronger parts and boilers.

In turn, this growth created more jobs in both rural and urban areas, which contributed to internal migration and the expansion of working-class populations in towns and cities.

For example, Manchester’s population grew rapidly during this period, rising from around 25,000 in the 1770s to approximately 75,000 by 1801.

In transport, several engineers who had studied Watt’s design applied its principles to new vehicles.

The first steam locomotives and steamships built upon principles established by Watt, though they employed high-pressure steam designs that differed from his low-pressure system.

Richard Trevithick, George Stephenson, and Robert Fulton all developed systems that owed their core mechanics to Watt’s pioneering work.

In education, Watt’s example encouraged the study of applied science, as technical colleges and engineering schools began to teach mechanical principles, and they used models of his engine to do so.

His clear documentation and technical diagrams provided future engineers with models for design and testing.

Today, many of these documents are preserved in the Library of Birmingham as part of the Boulton & Watt archives.

Across many areas of British industry, the influence of Watt’s invention could be seen in faster production and lower costs that changed where and how work took place.

His steam engine improved existing processes and changed the expectations of what machines could do, which laid the foundation for the modern industrial world.

In recognition of his achievement, the SI unit of power was later named the "watt" in 1889.

What do you need help with?

Download ready-to-use digital learning resources

Copyright © History Skills 2014-2025.

Contact via email

With the exception of links to external sites, some historical sources and extracts from specific publications, all content on this website is copyrighted by History Skills. This content may not be copied, republished or redistributed without written permission from the website creator. Please use the Contact page to obtain relevant permission.